Why Lined Steel Pipe is the Best Choice for Corrosive Environments

In industries where extreme chemical exposure, high temperatures, and abrasive materials are common, finding the right piping solution is critical. Lined steel pipe has become the preferred choice due to its exceptional durability, corrosion resistance, and long-term cost-effectiveness. The key is to specify the best high-performance protective lining to fortify your steel pipe for the specific conditions it will face in your particular context.

Unmatched Corrosion Resistance

Corrosion is the scourge of every industrial piping operation. Unlined pipes will deteriorate faster in nearly any environment, but when exposed to acids, solvents, and other aggressive chemicals, unprotected steel pipes simply fail rapidly.

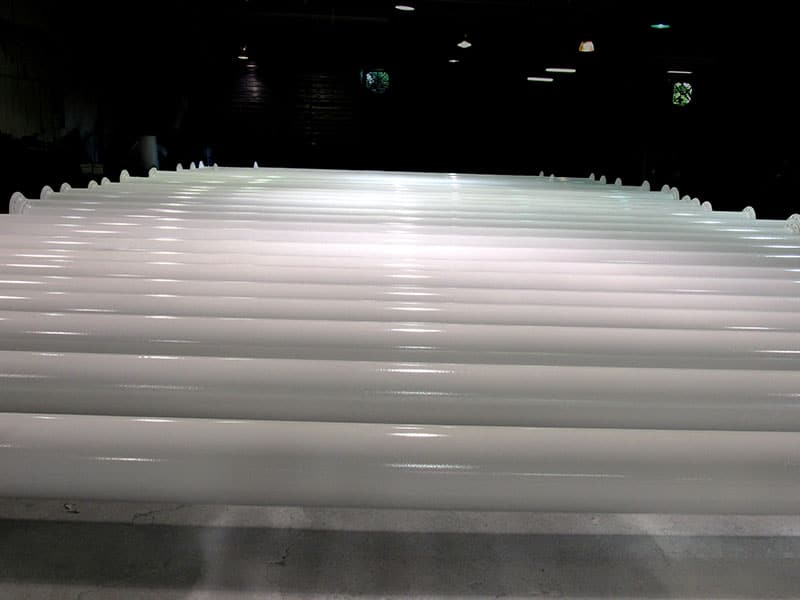

Take those same pipes and line them with a protective barrier, such as elastomers, fluoropolymers, or ceramic coatings, and even the most corrosive substances can be transported safely without compromising the pipe’s integrity.

Extended Service Life and Reliability

The combination of a robust steel exterior and a corrosion-resistant inner lining significantly enhances the lifespan of lined steel pipes. Where unlined steel pipes will inevitably succumb to pitting and rust, lined pipes will maintain their strength and structural integrity for far longer. This longevity alleviates the need for frequent repairs and replacements, making lined pipes the obvious choice, both functionally and economically, for chemical processing, water treatment, power generation, and any other industry involving corrosive chemicals.

Superior Performance in Abrasive Environments

In addition to chemical resistance, lined steel pipes are highly resistant to abrasion. Industries like mining, pulp and paper, and wastewater treatment often transport materials that can scrape, dent, puncture, or otherwise deform the interior surfaces of your piping system, causing blockages and leaks, and requiring expensive maintenance, unplanned stoppages, or worse.

Protective linings act as a tough, smooth, and flexible shield, reducing internal erosion and aiding in the smooth flow of material through the system. As a result, lined steel pipes require less maintenance and provide consistent performance for an extended life, even in high-stress environments.

Cost-Effective and Environmentally Sound

Lined steel pipes not only enhance operational efficiency but also offer long-term cost savings. Their durability reduces downtime and maintenance expenses, while their resistance to leaks confers substantial ecological benefits. By preventing premature pipe failures and hazardous material leaks, lined steel pipes contribute to safer, more sustainable industrial operations that benefit everyone.

Look to the Experts at Protective Coatings Inc.

For industries operating in corrosive and abrasive environments, lined steel pipe is the best choice. The experts at Protective Coatings (Proco) can analyze your system and identify the ideal optimal lining solution for attaining maximum performance, reliability, and longevity from your steel pipes.